If you’re just starting out in the world of RC drift cars, understanding the importance of proper maintenance is key to keeping your vehicle in its best shape. From cleaning and lubricating to checking and adjusting, there are a few simple yet effective ways to ensure your RC drift car performs at its peak. In this article, we’ll explore the best techniques for practicing RC drift car maintenance as a beginner, so that you can enjoy hours of uninterrupted drifting fun.

Table of Contents

Understanding the Basics of RC Drift Car Maintenance

What is RC drift car maintenance?

RC drift car maintenance refers to the routine care, cleaning, and repair of remote control drift cars. It involves various tasks to ensure the optimal performance and longevity of the RC drift car. These tasks include cleaning and maintenance of different components, inspection for damages and wear, lubrication, and troubleshooting.

Why is it important to practice RC drift car maintenance?

Practicing RC drift car maintenance is crucial for several reasons. Firstly, it helps to keep the car in optimal condition, ensuring smooth performance and longevity. Regular maintenance can prevent potential issues from escalating into major problems. It also helps to identify any wear and tear or damages, allowing for prompt repairs or replacements. Additionally, maintenance can enhance the overall drifting experience by improving control, handling, and responsiveness.

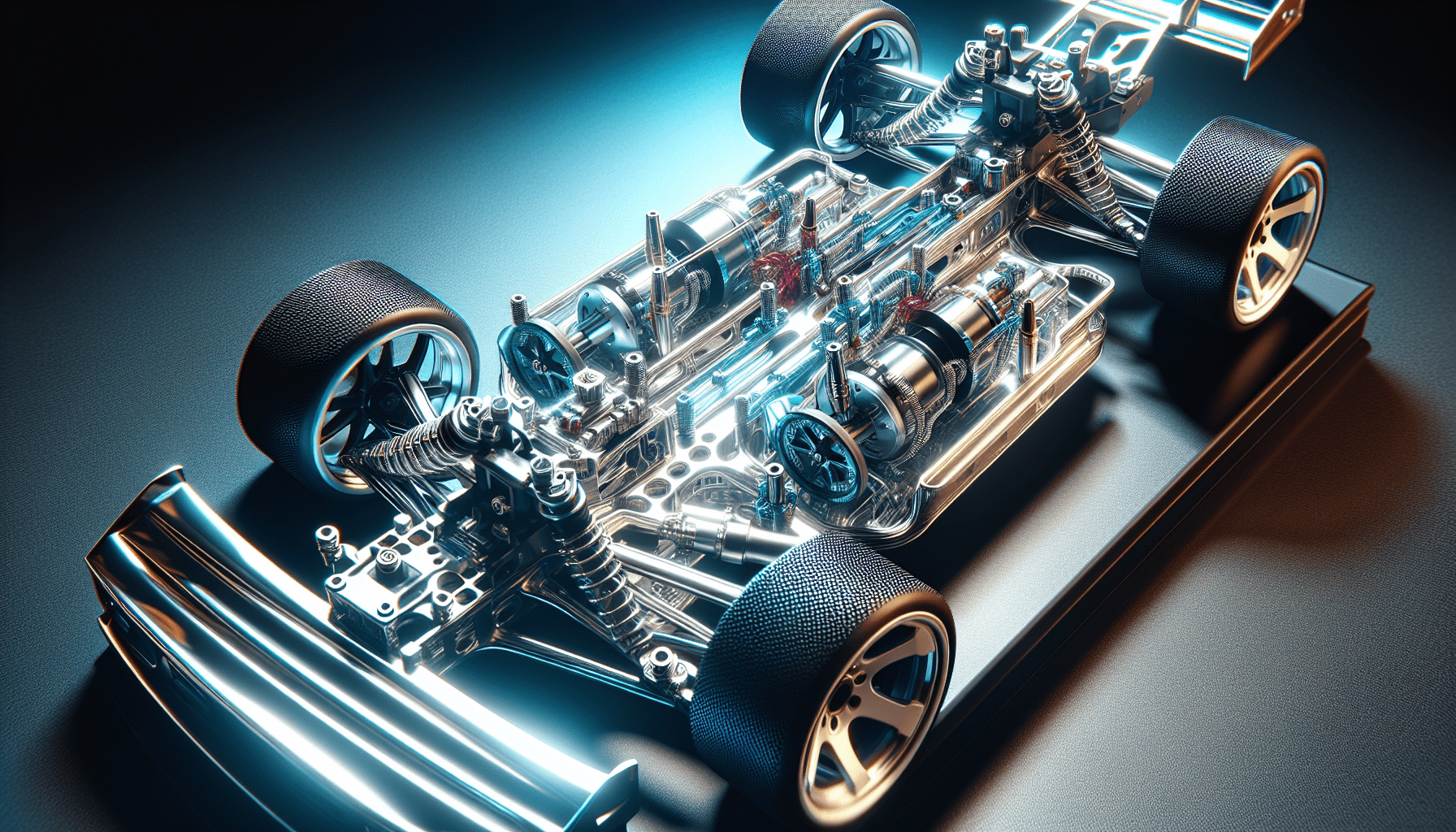

Getting familiar with the components of an RC drift car

Before diving into RC drift car maintenance, it’s important to familiarize yourself with the different components of the car. This will help you understand how the various parts work together and how to properly maintain them. The key components include the chassis, body, suspension system, drivetrain, tires, electronics, and wiring. Understanding how each component functions will enable you to perform maintenance tasks effectively and efficiently.

Tools and Equipment for RC Drift Car Maintenance

Essential tools for RC drift car maintenance

To practice RC drift car maintenance, there are several essential tools that you’ll need to have on hand. These include a set of screwdrivers (both Phillip’s head and flathead), hex wrenches, pliers, a hobby knife, needle-nose pliers, a soldering iron or gun, and a multimeter. These tools will assist you in disassembling and reassembling parts, performing minor repairs, and troubleshooting electrical issues.

Additional equipment for advanced maintenance

For more advanced maintenance tasks, there are additional tools and equipment that can be beneficial to have. These may include a tire balancer, shock pliers, shock oil, a pit mat, a battery charger, a brushless motor analyzer, and a motor cooling fan. While not essential for basic maintenance, these tools can enhance your ability to fine-tune and optimize your RC drift car’s performance.

Tips for selecting high-quality tools

When selecting tools for RC drift car maintenance, it’s important to choose high-quality ones that will withstand the demands of the hobby. Look for tools made from durable materials such as hardened steel or aluminum. Ergonomic handles can also make handling the tools more comfortable during longer maintenance sessions. Reading reviews and seeking recommendations from experienced RC drift car enthusiasts can help you make informed choices when purchasing your maintenance tools.

Cleaning and Maintenance Routine

Pre-run inspection and cleaning

Before each run, it’s essential to perform a pre-run inspection and cleaning. Start by visually inspecting the entire car for any visible damages or loose components. Check the tires for wear or damage, making sure they are properly inflated. Inspect the suspension system for any signs of damage or excessive play. Clean the body of the RC drift car using a soft brush or cloth, removing any dirt or debris that could affect performance or aesthetics.

Post-run cleaning and maintenance

After each run, take the time to clean and perform necessary maintenance tasks. Start by removing any dirt, dust, or debris from the chassis using a soft brush or compressed air. Inspect the drivetrain components, such as the gears and axles, for any signs of wear or damage. Clean the tires thoroughly to remove any residue and check for uneven wear. Lubricate the necessary parts, such as the suspension components and drivetrain, to ensure smooth operation.

Regular maintenance schedule for optimal performance

To maintain optimal performance, it’s important to establish a regular maintenance schedule for your RC drift car. This schedule will depend on your frequency of use, but for most enthusiasts, a monthly maintenance routine is recommended. This routine should include a thorough cleaning, inspection of all components, lubrication of moving parts, and addressing any issues or damages promptly. Adhering to a regular maintenance schedule will help prevent potential problems and extend the lifespan of your RC drift car.

Proper Battery Care and Charging

Choosing the right type of battery

When it comes to RC drift car batteries, there are various options available, including NiMH (Nickel-Metal Hydride) and LiPo (Lithium Polymer) batteries. Both have their advantages and disadvantages, so it’s important to choose the right type for your needs. NiMH batteries are generally more affordable and easier to handle, while LiPo batteries are lighter and provide higher performance. Consider factors such as budget, runtime requirements, and safety precautions when selecting the battery type for your RC drift car.

Battery maintenance and storage

Regardless of the battery type, proper maintenance and storage are essential for prolonging their lifespan and maintaining performance. Avoid overcharging or fully discharging the battery, as this can damage its cells. When not in use, store the batteries in a cool, dry place away from direct sunlight or extreme temperatures. It’s also recommended to use a battery storage bag to reduce the risk of fire or damage in case of a malfunction.

Safe charging practices

Safe charging practices are crucial to ensure the longevity and safety of your RC drift car batteries. Always use a charger specifically designed for the battery type you are using. Follow the manufacturer’s instructions for charging rates and durations, avoiding charging at high currents or for extended periods. Never leave the batteries unattended while charging and disconnect them from the charger once fully charged. Regularly check the charger for any signs of damage or malfunctions.

Tire Maintenance and Replacement

Inspecting and cleaning the tires

Regular inspection and cleaning of the tires are vital to maintaining control and performance during drifts. Before each run, visually inspect the tires for any signs of wear, cracking, or damage. Ensure they are properly inflated to the recommended pressure. After each run, clean the tires thoroughly to remove any debris or residue from the track. Using a soft brush or cloth, gently scrub the tires with mild soap and water, ensuring all dirt and rubber buildup is removed.

Recognizing signs of tire wear

Tire wear is inevitable with RC drift cars due to the nature of the sport. It’s important to recognize the signs of tire wear to know when they need to be replaced. These signs include uneven wear patterns, loss of grip or traction, visible cracking or splitting, and abrasions on the tire surface. Once the tires show significant signs of wear, it’s time to replace them to maintain optimal performance during drifts.

Replacing and balancing the tires

Replacing and balancing the tires is an important maintenance task to ensure even wear and consistent performance. To replace the tires, remove the existing ones by gently prying them off the wheels using a tire removal tool or a small flathead screwdriver. Install the new tires onto the wheels, ensuring a snug fit. Balancing the tires can be done using a tire balancer, which helps distribute the weight evenly for smoother and more controlled drifts.

Understanding Drivetrain Maintenance

Inspecting the drivetrain components

The drivetrain components of an RC drift car play a crucial role in transferring power and controlling the movement of the car. Regular inspection of these components is necessary to identify any issues or wear. Start by visually inspecting the gears, axles, and drive shafts for any signs of damage or corrosion. Check the tightness of screws and nuts, ensuring they are securely fastened. Listen for any unusual noises or vibrations that may indicate drivetrain problems.

Lubrication and maintenance

Proper lubrication is essential for the smooth operation and longevity of the drivetrain components. Use a lubricant specifically designed for RC drift cars to lubricate the gears, axles, and drive shafts. Apply the lubricant sparingly, ensuring all moving parts are adequately coated. Regularly clean the drivetrain components to remove any dirt or debris that may interfere with their functionality. Avoid using excessive force when cleaning or applying lubricant to prevent damage.

Troubleshooting common drivetrain issues

Despite regular maintenance, drivetrain issues can still arise. Some common issues include gear slippage, excessive noise, and poor power delivery. If you encounter any drivetrain problems, it’s important to troubleshoot them promptly. Check for loose screws or nuts that may need tightening. Inspect the gears for signs of wear or damage and replace them if necessary. If the issue persists, consult the manufacturer’s manual or seek advice from experienced RC drift car enthusiasts for further troubleshooting steps.

Suspension System Maintenance

Checking for suspension damage

The suspension system of an RC drift car is responsible for absorbing shocks and providing stability during drifts. Regularly checking for suspension damage is crucial to ensure safe and controlled performance. Inspect the suspension components, such as the shocks, springs, and control arms, for any signs of leaks, cracking, or excessive play. Test the suspension by pushing down on the car and observing if it rebounds smoothly or exhibits any abnormal behavior.

Cleaning and lubricating suspension components

Proper cleaning and lubrication of the suspension components are essential for maintaining their functionality and prolonging their lifespan. Clean the shocks, control arms, and suspension mounts using a soft brush or cloth to remove any dirt or debris. Lubricate the necessary parts, such as the shock shafts, with a silicone-based lubricant to ensure smooth movement. Avoid using excessive amounts of lubricant, as it can attract dirt and interfere with the suspension’s performance.

Adjusting suspension setup for drift performance

To optimize drift performance, it’s important to adjust the suspension setup of your RC drift car. This includes setting the suspension stiffness, ride height, and damping characteristics. Experiment with different setups to find the optimal balance between stability and agility. Make small adjustments at a time, keeping track of the changes and their effect on the car’s handling. Consulting online resources or seeking advice from experienced drifters can provide valuable insights for achieving the desired suspension setup.

Body and Chassis Maintenance

Cleaning and protecting the RC drift car body

The body of an RC drift car requires regular cleaning and protection to maintain its appearance and integrity. Clean the body using a mild soap and water solution, gently removing any dirt or debris. Avoid using abrasive materials or harsh chemicals that could damage the paint or decals. After cleaning, dry the body thoroughly with a soft cloth to prevent water spots. Apply a protective spray or wax to keep the body’s finish in good condition and protect it from scratches or UV damage.

Maintaining the chassis and frame

The chassis and frame of an RC drift car provide the structural support and stability for the entire vehicle. To maintain these components, regularly check for any signs of damage or stress, such as cracks or bends. Clean the chassis and frame using a soft brush or compressed air to remove any dirt, dust, or debris that may accumulate. Lubricate the necessary hinge points or moving parts to ensure smooth operation. Address any issues or damages promptly to prevent further complications.

Replacing and customizing body parts

Over time, the body parts of an RC drift car may become worn, damaged, or outdated. Replacing and customizing these parts can breathe new life into your drift car and allow for personalization. When replacing body parts, ensure they are compatible with your specific model. Many manufacturers offer a wide range of aftermarket body parts, allowing you to customize the look of your RC drift car. Take the opportunity to explore different body styles and decals to reflect your own personality and tastes.

Electronics and Wiring Maintenance

Inspecting the electronic components

The electronic components of an RC drift car, including the receiver, servo, and ESC (Electronic Speed Controller), require regular inspection to ensure proper functionality. Visually inspect these components for any signs of damage, loose connections, or corrosion. Check the wires for any fraying or exposed connectors. Test the range and responsiveness of the receiver and servo to ensure they are working correctly. Any issues or damages should be addressed promptly to prevent further complications.

Cleaning and protecting wiring connections

The wiring connections in an RC drift car play a critical role in transmitting signals and power. Keeping these connections clean and protected is essential for optimal performance and reliability. Use a contact cleaner or isopropyl alcohol to clean the connectors, ensuring they are free from dirt or corrosion. Apply a small amount of dielectric grease to the connectors to protect them from moisture and promote better conductivity. Regularly check the wiring connections for any signs of wear or loose contacts.

Safely handling electronic repairs or upgrades

If you need to perform electronic repairs or upgrades on your RC drift car, it’s important to handle them safely and cautiously. Always disconnect the battery before working on any electronic components to avoid accidental short circuits. Follow the manufacturer’s instructions and guidelines when performing repairs or upgrades. If you are unsure or inexperienced with electronic work, it’s recommended to seek assistance from a knowledgeable hobbyist or professional to ensure the job is done correctly.

Tips for Troubleshooting and DIY Repairs

Common RC drift car issues and troubleshooting steps

While regular maintenance can minimize potential problems, RC drift cars may encounter issues from time to time. Some common issues include steering drift, intermittent power loss, and unresponsive controls. Troubleshooting these issues can involve checking connections, recalibrating the ESC, inspecting the steering mechanism, or adjusting the radio settings. Consult the manufacturer’s manual, online forums, or seek advice from experienced drifters for specific troubleshooting steps based on your RC drift car model.

Basic DIY repairs for minor damages

For minor damages such as broken body parts or loose screws, basic DIY repairs can save you time and money. Keep a stock of spare parts that are commonly prone to damage, such as body clips, shock towers, or suspension arms. With the appropriate tools, you can easily replace these parts by following the manufacturer’s instructions. Tighten loose screws or nuts using the correct size of screwdriver or wrench. DIY repairs not only enhance your maintenance skills but also minimize downtime and keep you on the track.

Knowing when to seek professional help

While DIY repairs are suitable for minor damages, some issues may require professional assistance. If you encounter complex electrical problems, motor or ESC malfunctions, or major structural damages, it’s advisable to seek help from experienced RC drift car specialists. They have the expertise and tools to diagnose and address more intricate issues effectively. Additionally, seeking professional help can provide invaluable guidance and knowledge, allowing you to further enhance your skills and understanding of RC drift car maintenance.

In conclusion, understanding the basics of RC drift car maintenance is essential for all RC drift enthusiasts. By regularly cleaning, inspecting, and maintaining the various components of your RC drift car, you can ensure optimal performance and longevity. Proper battery care, tire maintenance, drivetrain maintenance, suspension system maintenance, body and chassis maintenance, and electronics and wiring maintenance are all crucial aspects of RC drift car maintenance. By following maintenance routines, selecting high-quality tools and equipment, and knowing when to seek professional help, you can enjoy a smooth and exciting RC drifting experience. Remember, the key to successful RC drift car maintenance is staying proactive and attentive to the needs of your car. Happy drifting!